I am excited about the future as we stand on the precipice of the next wave of digital transformation; it is becoming increasingly clear that our immediate future will demand more computing - more integrated chips, more programming, more data storage, and better connectivity than ever before. This is driving an unprecedented surge in the semiconductor industry, a critical component that forms the backbone of today's technological advancements. According to McKinsey, the global semiconductor industry is poised for a decade of growth and is projected to become a trillion-dollar industry by 2030.

However, the semiconductor components necessary for the leap in digital transformation are just the beginning. More and more organizations are realizing that a holistic approach toward digital transformation entails integrating the value chain of Silicon to Systems to the Cloud (S2S2C). This is more than just a technological evolution; it marks a comprehensive shift in how organizations approach and implement digital transformation. In this paper, we will dive into the holistic approach necessary to build and sustain an integrated S2S2C value chain necessary for the future of digital transformation.

The integration of silicon represents the physical transformation that lays the foundation for a digitally enhanced future. As the starting point, silicon-based technologies enable the performance and efficiency required to fuel the modern connected world. The integration of silicon into the systems value chain requires planning and expertise for components to communicate and collaborate effectively with each other. The final move to the cloud epitomizes the shift toward servitization and scalability. In the product-enabled services world, the vast interconnected network of systems finds its ultimate expression, offering unparalleled flexibility and accessibility. Yet, this introduces new security, governance, and management complexities that must be skillfully navigated.

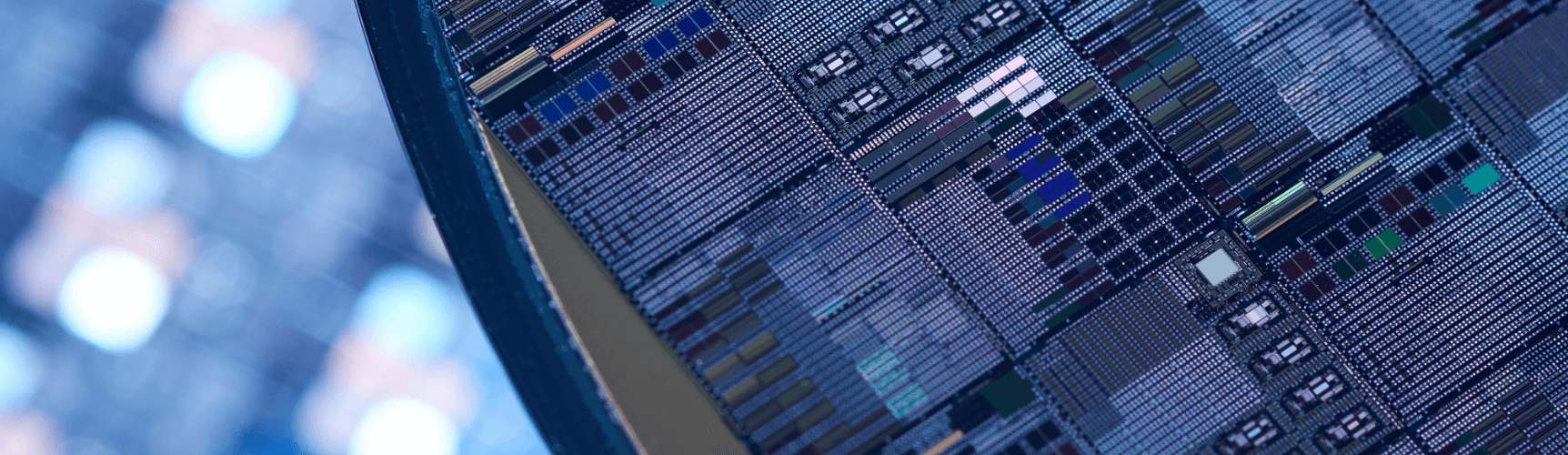

The silicon layer of this value chain forms the foundation upon which everything else is built. Silicon engineering plays a vital role in this landscape, providing the necessary building blocks for various applications. This includes the creation of Application Specific Integrated Circuits (ASICs), which are tailored for specific functions, offering efficiency and performance optimization.

As technology progresses, the industry is witnessing a trend towards more customized solutions. Strategic product considerations such as differentiation, performance optimization, security, and better control & integration are driving the development of custom chips, including System-on-Chips (SoCs), for specific use cases. These custom solutions allow product organizations to build to have a competitive edge. These custom chips, tailored to meet the unique requirements of a particular application or industry, require significant investment and have a long development cycle. However, they offer the potential for superior performance, efficiency, and functionality compared to general-purpose chips.

In the hi-tech industry, custom chips power artificial intelligence (AI), machine learning (ML), and quantum computing applications. These chips are designed to handle massive computational requirements, enabling faster processing, greater accuracy, and lower power consumption. Similarly, custom chips are used in various applications, from diagnostic equipment to implantable devices in the healthcare industry. Proprietary chips are also being used to enhance the performance and functionality of consumer electronics devices such as wearables, smartphones, tablets, and smart home devices.

The term 'systems' encompasses both the platforms and products that act as key building blocks, empowering Original Equipment Manufacturers (OEMs) to create, innovate, and deliver a diverse range of offerings. The platforms function as the underlying architecture that hosts and connects various components, while the products are the tangible implementations of that architecture. Together, they form a critical link in the technological landscape, enabling the construction and functionality of an array of devices and solutions.

The box and inside the box

Each physical product consists of a "box (enclosure)". Mechanical engineering forms an essential aspect here and also involves engineering analysis, stress testing, thermal studies, and feasibility evaluations to ensure structural integrity and reliability. The system design goes beyond mere functionality and compliance with industry norms and safety guidelines. It also embodies thoughtful user experience (UX) and innovative industrial design, meeting not just market expectations but also enriching the interface between humans and machines.

Inside 'the box,' OEMs shift their focus to embedded engineering, orchestrating the complex interplay between electronics and software. The alignment of software with hardware, from custom microcontrollers to specialized firmware, leads to optimized performance, cost-effectiveness, and responsiveness, seamlessly bridging the tangible 'box' with the intangible digital world.

The cloud aspect of our S2S2C value chain signifies the emergence of product-enabled services. Today, we also observe physical products augmented with digital capabilities, creating dynamic and interactive offerings in their connected state. Such a fusion allows OEMs to innovate beyond static goods, adding value through software, data analytics, predictive analysis, and flexible consumption models.

These product-enabled services form an ecosystem that is reshaping customer experiences and opening new revenue streams. As-a-service offerings provide customers access to products and services on a flexible basis without the need to own them outright. A prominent example is Device-as-a-Service (DaaS), where customers pay for the use of a device rather than purchasing it, allowing for adaptable usage and cost-effective scaling. The integration of predictive analysis within this ecosystem facilitates a more intelligent and responsive approach to product development and delivery. Leveraging data insights and machine learning, OEMs can anticipate customer needs, optimize performance, and personalize experiences.

However, delivering these product-enabled services requires the integration of key ecosystem players. Hyperscalers provide the infra for large-scale cloud services, communication service providers ensure seamless connectivity, data providers offer the necessary data for analytics, analytics service providers process and interpret this data, and Over-The-Top (OTT) platforms deliver the services to the end-users.

The true success of a digital transformation lies in the seamless integration of these three areas - Silicon, Systems, and Cloud. Each part of the value chain is interconnected, and a weakness in one area can undermine the entire transformation.

This interconnected value chain does more than just align with the demands of a smart, connected world. It maximizes opportunities, builds lasting relationships with customers, and defines the very essence of modern digital transformation.

At Quest Global, we take pride in our profound domain knowledge and expertise across a broad spectrum of industries, including aerospace and defense, automotive, energy, healthcare and medical devices, hi-tech, rail, and semiconductors. We have been guiding our clients to embrace this integrated value-chain approach to their digital transformations through:

Quest Global will stand as your end-to-end digital transformation partner that adapts and evolves to the ever-changing demands of the new world. Intertwining technological innovation with a cohesive digital ecosystem, we ensure your growth, agility, and competitiveness.

VP - Strategy & Solutions, Semiconductor Vertical

Quest Global