Machine Migration

Aircraft component manufacturer wanted to replace 12 old CNC M/c (Mitsubishi) to 6 high tech M/c (Makino MAG1) in order to improve process and manufacturing efficiency.

Customer wanted to understand actual value benefits that can be realized and investment required for the project well before the plan is executed in real time.

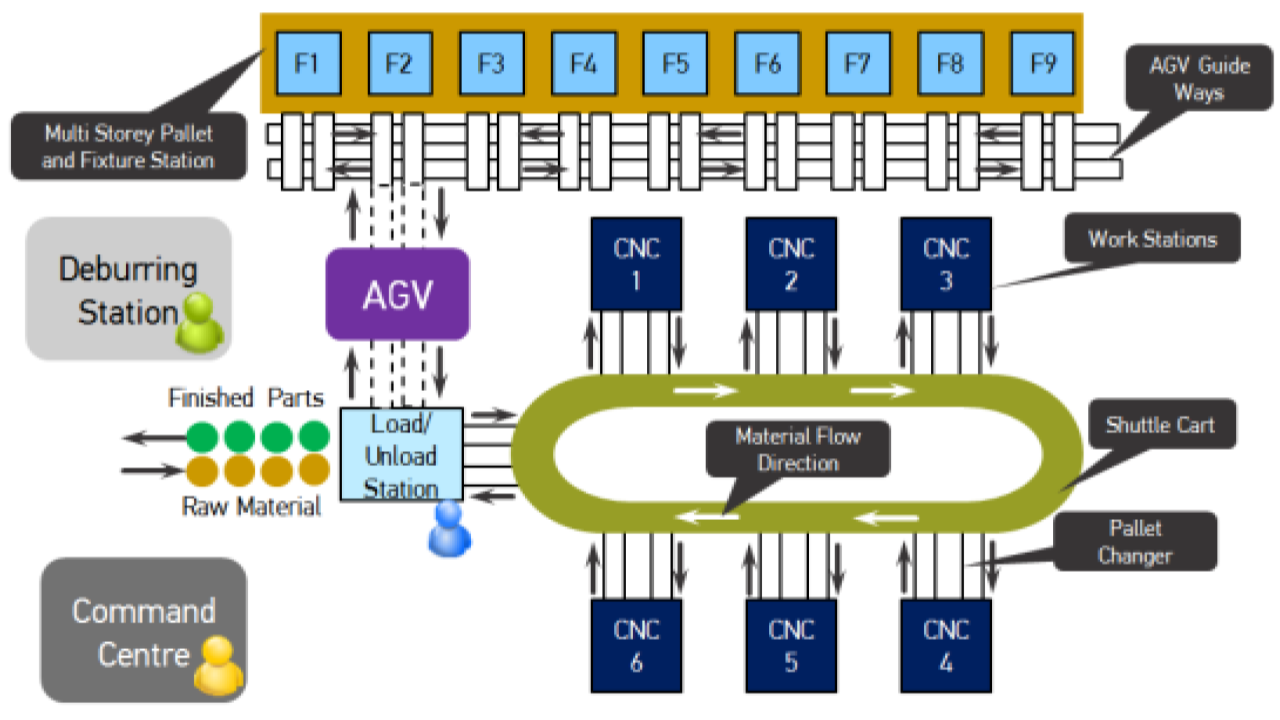

All new Machines to be part of flexible manufacturing cell with automated guided vehicle (AGV) for pick and place.

To develop 3D model of cell layout for new machines with robots and validate the manufacturing efficiency through virtual process simulator