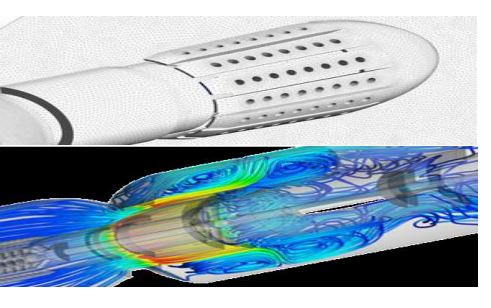

Wells are continuing to increase in complexity in the Oil & Gas industry. Pressure pulse telemetry is a key technology allowing status of downhole operations to be communicated to the surface, improving efficiency of the overall operation. Understanding mechanisms creating these pulses and their interaction with the surrounding flow are important to ensure a robust design. CFD is becoming an increasingly important tool to reduce product development time.