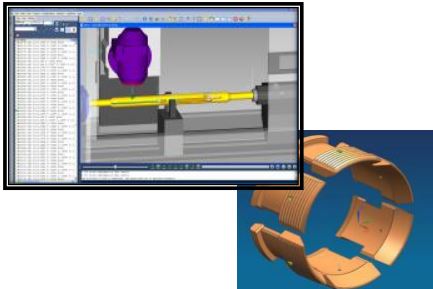

CNC Programming Support Using Esprit and NX

A manufacturing unit of an oil and gas major used Esprit and NX for CNC programming. Set up data sheet was created manually. Utilization of senior programmers was not managed well which eventually led to a high-cycle time.

The challenge was to reduce high-cycle time by adopting automated programs.