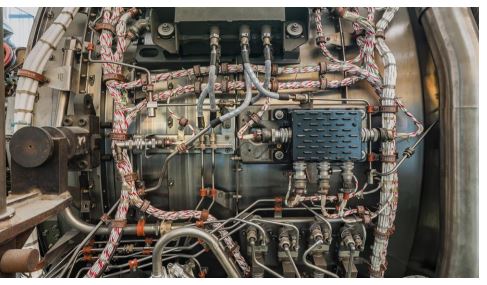

Standardization of loom assembly across aero engines

A global aero engine manufacturer needed a new loom assembly design for every engine program – the activity was always on the critical path of Engine Development Program

Standardize Flight Test Instrumentation (FTI) lead-out loom assembly through: