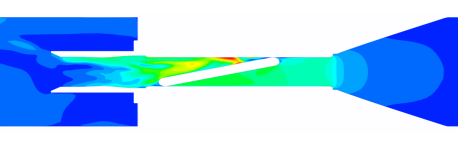

Simulation is increasingly being used in the development cycle for new products, both to augment and offset costly testing of prototypes. CFD can be used to augment testing requirements by allowing proper selection of motors, and can be used to down select designs before going through a full prototype and testing phase. This leads to an overall reduction in development cycle time and costs.