A major component inspection equipment OEM from Europe, wanted to solve their problem of equipment availability during integration testing. All departments were vying for availability of the equipment for integration testing. Due to lack of availability of the equipment and the need to meet the delivery schedule, equipment was being shipped without complete testing by all departments

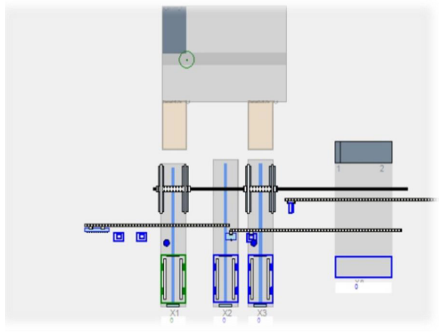

QuEST proposed to develop a feature rich equipment simulator software with high level of configurability that could