The article talks about the ADAS service provided by QuEST to its customers that helps them save cost and reduce time to market.

Background

Regarded as the bridge between traditional cars and the cars of tomorrow, ADAS as a technology is enabling vehicles to perform more and more tasks intuitively and independently.

According to a recent survey by Roland Berger, the increasing demand for basic driver assistant features will make this technology a common feature in every new vehicle sold by 2025. 85% of vehicles produced globally in 2025 will have some level of driving automation. Key sensor equipment such as front radars and cameras will become standard over the next few years.

Both, the US and the EU have already mandated that all vehicles must be equipped with autonomous emergency braking systems and forward collision warning systems, making ADAS the core to make cars safer and reduce human error.

The Challenge

Customers, both OEM and Tier1s often find it difficult to balance time to market with cost effectiveness for ADAS solutions. QuEST partners with them to enable shorter development cycles with frequent software releases, delivering a competitive advantage to the OEM or supplier.

Some of the roadblocks that customers face with ADAS implementation include:

Pre-requisites

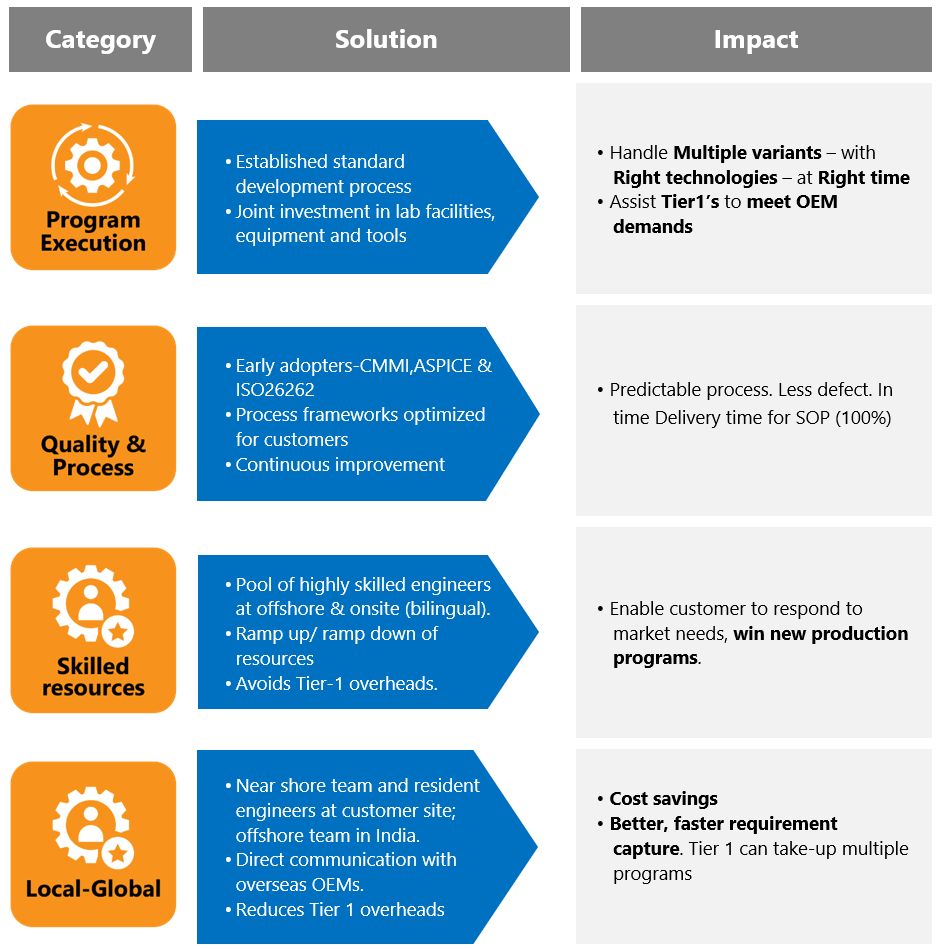

It is important to have a differentiated approach to solve the problems of OEMs and Tier 1s.

OEMs deal with the vehicle level deployment including regulations and standards to meet the homologation requirements of a vehicle made or imported into that country.

Some of the major OEM requirements include:

Tier1’s on the other hand focus more on the product level design, development and testing. Some of the key Tier1 requisites include:

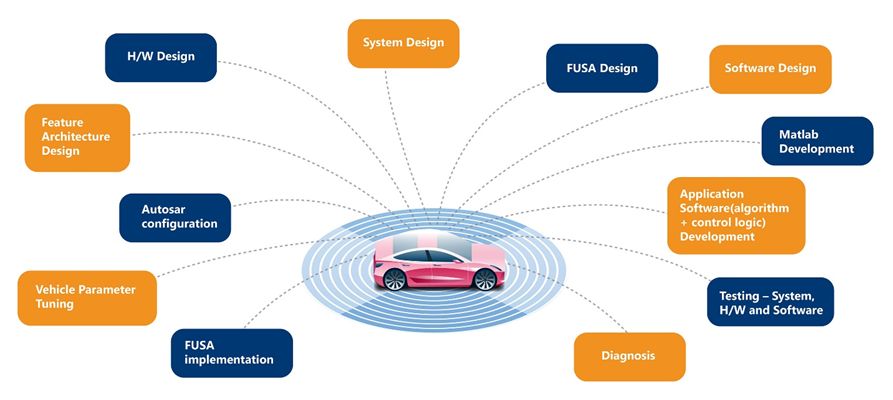

QuEST Solution

At QuEST, we follow a three-stage engagement with our customers to help them overcome their challenges:

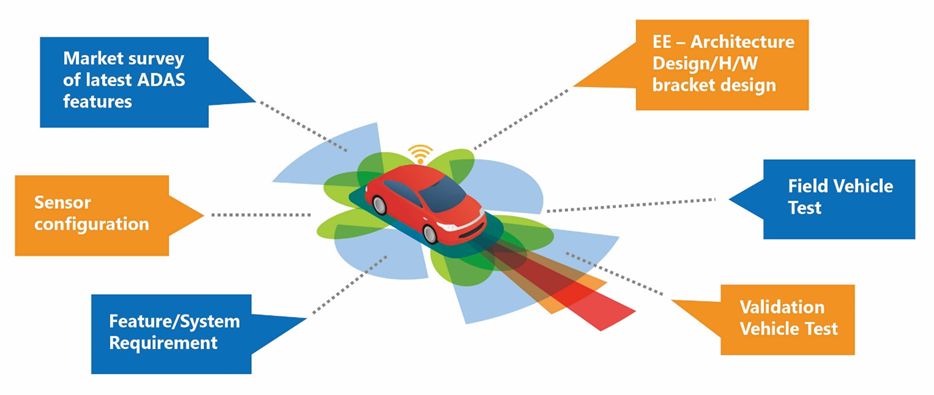

Understanding and baselining customer requirement is the first stage. This includes several aspects like:

Step 1: Problem statement dissection with scope clearance and expectations

A large pool of engineers with expertise in ADAS, engine & powertrain ECUs, help to measure the impact/frequency of software releases and plan resource distribution to meet the ramp up demands of ADAS deployment across multiple variants/models. Sometimes this may range from one team, one variant, up to five teams, eight variants.

Step 2: Proposal with Cost and Timelines

Customers always want a predictable process to ensure 100% delivery on time every time.

Step 3: Metrics Driven Execution and Delivery

Some of the key solutions that help our customers to achieve this are:

To summarize, the differentiators that QuEST offers to its customers as an ADAS service partner include: